How 3D Printing Is Revolutionizing Custom Manufacturing

The advent of 3D printing has significantly transformed the landscape of custom manufacturing. This technology facilitates rapid prototyping, allowing businesses to iterate designs swiftly and efficiently. Moreover, it supports mass customization, enabling products tailored to specific consumer preferences. As industries explore these capabilities, they encounter both opportunities and challenges. Understanding the implications of this shift is crucial for stakeholders aiming to stay competitive in an evolving market. What lies ahead for manufacturing in this context?

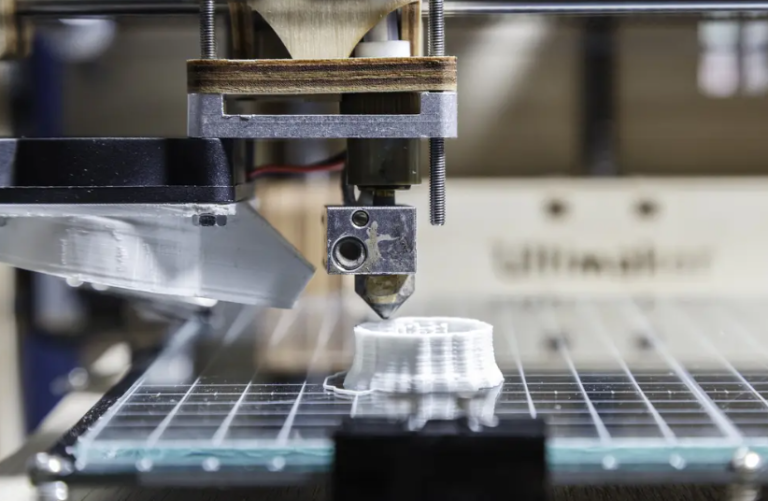

The Impact of 3D Printing on Design and Prototyping

As companies increasingly adopt 3D printing technology, the influence on design and prototyping processes becomes increasingly evident.

This innovation facilitates iterative design, allowing designers to rapidly prototype and refine concepts with unprecedented speed. The capability to rapidly produce functional prototypes encourages experimentation and reduces the barriers to creative exploration, ultimately empowering designers to push boundaries and explore new possibilities in custom manufacturing.

Cost Efficiency and Reduced Production Times

While traditional manufacturing methods often involve significant setup costs and lengthy production timelines, 3D printing offers a transformative approach that enhances cost efficiency and accelerates production durations.

Through automation integration and supply chain optimization, companies can minimize waste and reduce overhead. This efficiency not only lowers costs but also allows for rapid response to market demands, fostering a more adaptable manufacturing environment.

Customization and Personalization in Manufacturing

With the rise of 3D printing technology, the potential for customization and personalization in manufacturing has expanded significantly.

This innovation facilitates mass customization, enabling manufacturers to produce personalized products tailored to individual consumer preferences.

As a result, businesses can enhance customer satisfaction and foster brand loyalty, while consumers enjoy the freedom to select unique designs, materials, and functionalities that meet their specific needs.

See also: Exploring the Role of Technology in Mental Health Care

Sustainability and the Future of 3D Printing

How can 3D printing technology contribute to a more sustainable future in manufacturing?

By utilizing biodegradable materials and reducing waste, 3D printing minimizes environmental impact.

Additionally, advancements in energy-efficient printing processes can significantly lower energy consumption.

As industries adopt these practices, 3D printing not only enhances customization but also fosters a more eco-friendly production paradigm, aligning with the growing demand for sustainability.

Conclusion

In an age where mass production reigned supreme, the rise of 3D printing emerges as a paradox. While traditional manufacturing often celebrated uniformity, this technology champions individuality, crafting bespoke items with remarkable ease. Yet, as industries embrace this revolution, the irony lies in the fact that the quest for personalization may ultimately lead to an unexpected homogeneity of choices. Thus, what began as a tool for unique expression may inadvertently standardize our very preferences in the relentless pursuit of customization.