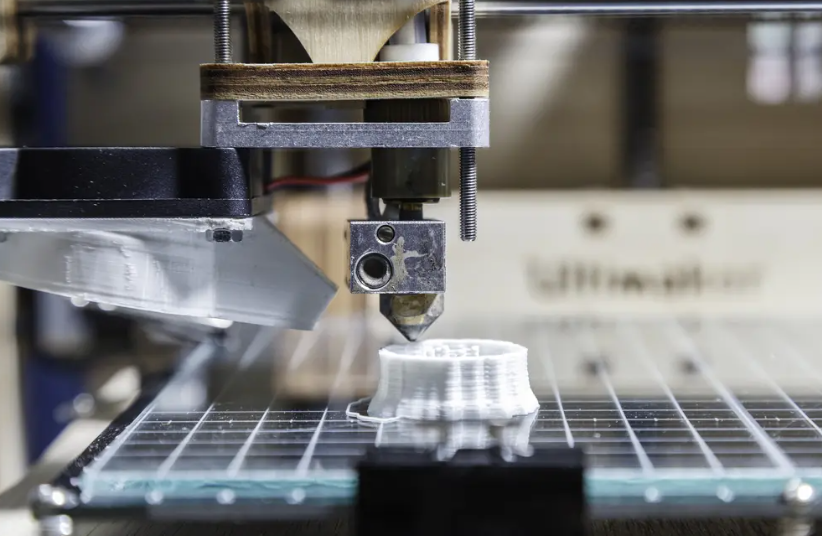

How 3D Printing Is Changing the World of Manufacturing

3D printing technology has significantly transformed the manufacturing sector. Its additive process allows for intricate designs and reduces material waste, presenting a stark contrast to traditional manufacturing methods. Key industries, including automotive and aerospace, are increasingly adopting this technology to enhance efficiency and customization. As advancements continue, it becomes essential to examine the implications of these changes on production practices and material sustainability. What lies ahead for the future of manufacturing?

The Evolution of 3D Printing Technology

Although 3D printing technology has roots that date back to the 1980s, its evolution has accelerated dramatically in recent years, driven by advancements in materials, software, and machine capabilities.

Historical milestones such as the development of stereolithography and selective laser sintering have paved the way for these technological advancements, enabling increased precision and customization that empower industries to embrace innovative manufacturing processes and design freedom.

Key Industries Embracing 3D Printing

As industries increasingly recognize the advantages of additive manufacturing, several sectors have rapidly adopted 3D printing to enhance their production processes and product offerings.

Notably, automotive applications utilize 3D printing for prototyping and lightweight parts, while aerospace components benefit from the technology’s ability to create complex geometries.

These advancements allow for greater design freedom and reduced lead times, positioning these industries at the forefront of innovation.

See also: Exploring the Role of Technology in Mental Health Care

Benefits of 3D Printing in Manufacturing

The transformative potential of 3D printing in manufacturing lies in its ability to streamline production processes and reduce costs.

By enhancing cost efficiency, manufacturers can minimize waste and lower material expenses.

Additionally, 3D printing offers remarkable design flexibility, allowing for the creation of intricate geometries that traditional methods cannot achieve.

This adaptability fosters innovation, empowering manufacturers to respond swiftly to market demands and consumer preferences.

Future Trends and Innovations in 3D Printing

Advancements lie ahead for 3D printing in manufacturing. Future trends indicate a significant shift toward sustainable materials, enhancing environmental responsibility.

Innovations in rapid prototyping will streamline production processes, allowing for quicker iterations and reduced waste.

As technology evolves, the integration of artificial intelligence and machine learning may further refine design capabilities, fostering unprecedented customization and efficiency within the manufacturing landscape.

Conclusion

In conclusion, 3D printing is poised to redefine the manufacturing landscape, evidenced by a remarkable projection that the global 3D printing market is expected to reach $34.8 billion by 2024. This transformative technology not only enhances design capabilities and reduces production waste but also promotes sustainability through innovative material use. As industries increasingly adopt 3D printing, the integration of advanced technologies will further accelerate its impact, shaping a more efficient and environmentally conscious manufacturing future.